A clean room is a controlled environment that has very low level of pollution particles. They are devoid of potentially harmful particles in the air. These rooms are extremely crucial and find their applications in a wide range of sectors. For instance, they are employed in pharmaceuticals, biotechnology and electronics. This post will explain why an ISO 3 fan filter unit for clean room is so critical. We will learn how it keeps us safe and healthy. And we will discuss what you should know before you step into a clean room

Even though an ISO 3 clean room has several benefits, those benefits are really crucial for the workers and what is being manufactured. The primary advantage is shielding employees and products from dangerous particles, microbes, or viruses. ISO 3 clean room air is a billion times cleaner than indoor air. The air within an ISO 3 clean room contains less than 1000 particles per cubic meter compared to millions of particles in normal indoor air!

Sensitivity is at a premium when it comes to making, say, medicines or electronics, whether it is a few molecules, atoms or molecules of something (contaminant) that can cause trouble. Such as, if medicine becomes contaminated, it might misfire or be harmful. This is why the pharmaceutical and electronics industries use ISO 3 clean rooms to ensure that the things they produce are safe for humans and function as intended

ISO is an acronym for International Organization for Standardization. It is the organization responsible for setting regulations and standards for many industries. In terms of the manufacturing industry, clean room standards are determined by a certain rule of ISO 14644-1. There are six grades of clean rooms, and ISO 3 is one of the cleanest grades available. An ISO 3 clean room is the more specific category where there are no more than (3.5 microns or larger) in the air in one cubic foot of space. It is a very secure setting for creating delicate products.

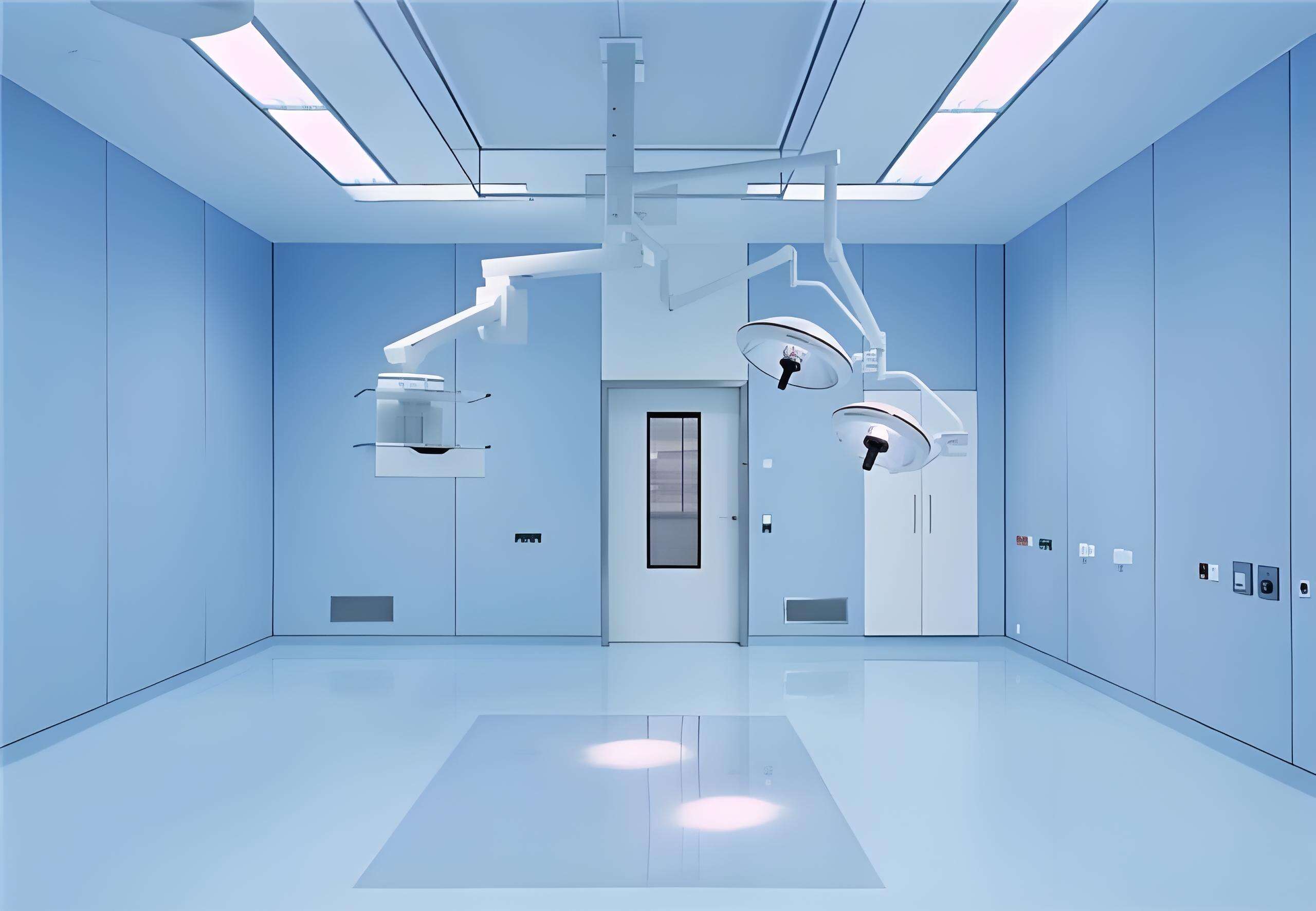

ISO 3 rating is very stringent, so the clean room must be designed and earned with utmost care. All pass through box clean room design must have elements to prevent contamination. Things like air filters to scrub the air and robust, sealed walls that keep particles out. The choice of materials that will compose the clean room also has to be made in a way such that they do not release particles that could contaminate the clean room.

Keeping the clean room is another critical factor. The maintenance of the clean room door is paramount to maintaining their ISO 3 rating. Everything that goes on inside the clean room can dislodge particles and render the air less clean. Cleaning and disinfecting is regularly done so as to minimise any risks of contamination. A clean room must be cleaned using special tools and supplies that are appropriate for handling in a clean room, keeping everything as clean as possible.

Essentially, ISO 3 clean rooms save and protect us. These clean rooms can limit the spread of airborne diseases and reduce contamination. A clean room affords the right environmental controls, including temperature, humidity, and airflow. This is especially relevant during outbreak or pandemic of a potentially serious contagion. The clean rooms that have been used in hospitals or medical labs are excellent in preventing the spreading of diseases from one to another person.