It is very important that products made are clean. If they are not clean, they may not function correctly and, in extreme cases, could harm an individual. That’s where ISO 7 type cleanrooms come into play. These specialized rooms are designed to maintain such stark cleanliness that products can be developed safely and accurately. So here in this text, we are going to find out more about these cleanrooms, what they are used for, and how they help improve the products and their safety for everyone

This is the name of a specific rule made by a group called the International Organization for Standardization, commonly shortened to ISO. This group creates regulations that help guarantee cleanrooms are sanitised enough to produce quality products. ISO 7 standard also describes the number of the kingdoms of millionths of a meter (microns) particles found in the cleanroom air and how frequently it will require air changes.

In an ISO 7 cleanroom, there can be no more than 352,000 tiny particles in a cubic meter of air. That might sound like a big number, but remember, it is very important to keep that number low! And to ensure that the cleanroom remains clean, the air must be exchanged at a minimum of 15 times per hour. This means clean air gets pumped in continuously as dirty air gets pushed out. This helps maintain a safe environment for manufacturing

Huajing is one such company that manages clean manufacturing well. They even use Huajing ffu clean room to assist in making their products. Huajing ensures that the products it produces are safe and of the highest quality with these cleanrooms. Cleanrooms help them minimize the risk of dirt and other contaminants entering the products during their manufacturing process.

In this day and age, consumers are more concerned than ever about the safety of the products that they purchase. They want assurance that the products they use are safe for them and their families. All of these are allaying the need for safety and quality, and Huajing is met with market demand by adopting Huajing ventilator filter unit in their manufacturing processes.

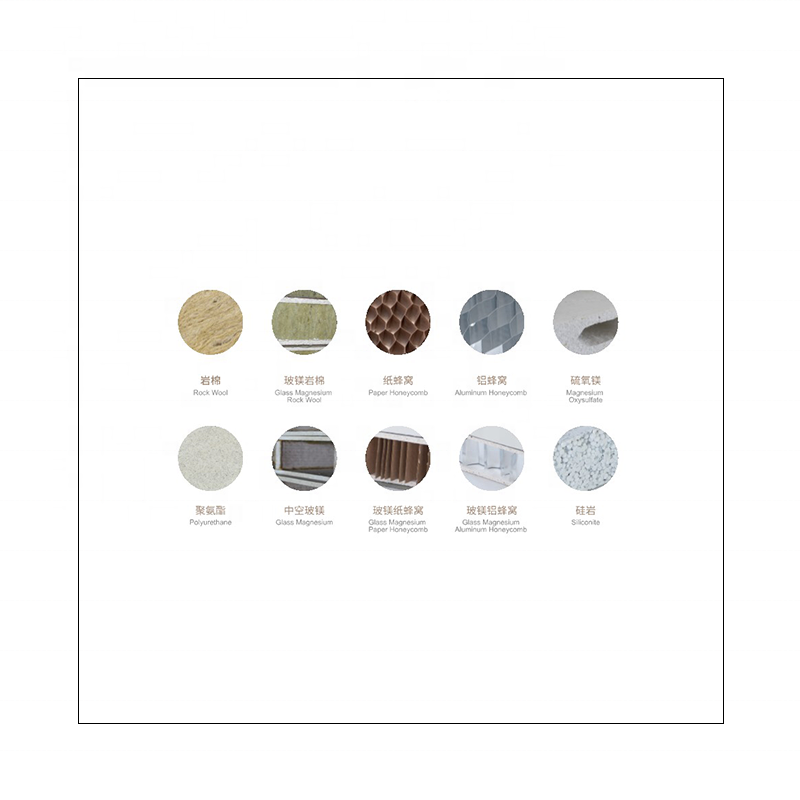

It all starts with the materials that are used, with a focus on product safety. Huajing goes the extra mile to source all their raw materials from trusted suppliers that uphold high quality control standards. This ensures that the materials are tested and approved safe before they are used for production. When the materials are finally received, the production processes are tightly controlled to minimize the risk of contamination, and to guarantee that everything coming out is consistent and reliable.

These advancements are all fronted by Huajing in clean manufacturing. They manufacture products that meet or exceed Huajing fan filter unit for sale standards. This focus on safety and quality helps set them apart from their competitors. It also enables them to cater to the needs and expectations of today's consumers, who demand safe, high-quality products.