Due to several reasons, sandwich panel steel is very widely used nowadays. People are using it to construct all kinds of things around the world — not just homes but large buildings as well. This unique material is strong, light and easy to work with, allowing you to build everything from large structures to the smallest of devices. Sandwich panel steel is according to different kind of metals being tightly pressed. Through this method, a tough and resilient substance is produced that may be located in all sorts of constructions, from buildings to houses to automobiles.

The great thing about sandwich panel steel is its strength. This strength means that it can support very big buildings and as well as resist the harshest of weather conditions, such as strong winds and heavy rain. This fact helps in making it a safe option for the builders. Sandwich panel steel is also lightweight, making it yet another useful aspect. This makes it lighter to transport and fit at the site, thereby saving time and labor during construction. Additionally, sandwich panel steel is vapour, fire, and sound-resistant. Very few projects can be completed without using this equipment. They are confident it will lead to robust, secure structures and leave them with clean air.

Revolutionizing Building- Sandwich Panel Steel This material became widely available only recently, giving architects the freedom to design buildings in new and exciting ways that were impossible before. Due to the lightweight nature of sandwich panel steel, very large open spaces can be created within buildings. Because it does not require many supports or thick load-bearing walls, architects can create interiors that feel spacious and airy. Having such flexibility allows architects to be more creative and innovative, resulting in beautiful, one-off unique designs.

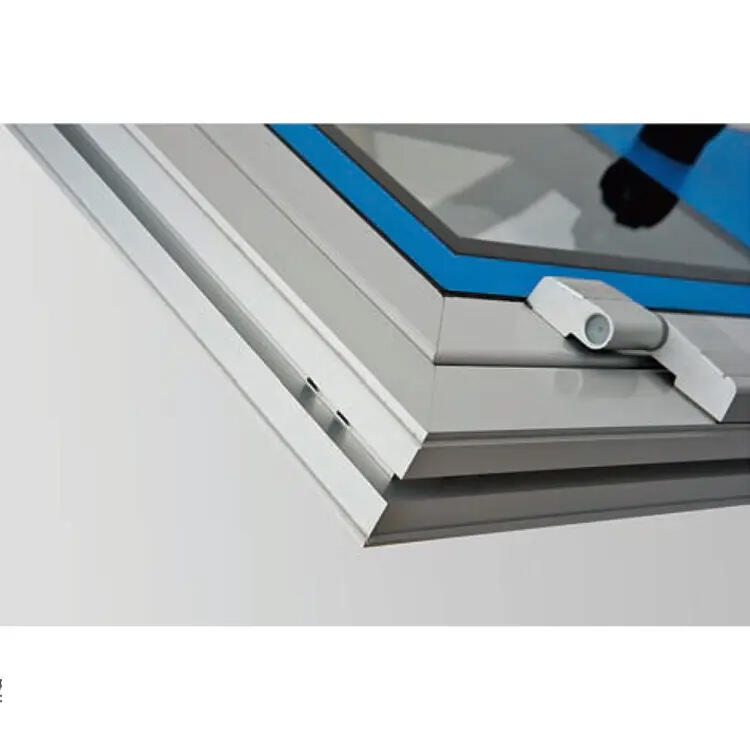

We can see how sandwich panel steel is made if we take a closer look at it. It is made up of the two strong layers of metal encasing an insulating layer. This insulation can be composed of foams or fiberglass. The sandwich configuration allows for even load distribution which gives it strength and rigidity. The insulating layer also helps maintain comfortable temperate levels in the interiors of the building, regardless of the external climate, hot or cold. This feature can provides savings on energy bills because the building will stay warm in winter and cool in summer. This makes sandwich panel steel highly versatile and easy to work with for any kind of design project.

There are several environmental Products benefits of sandwich panel steel as well. When builders use this material, they are able to reduce the overall amount of energy required to heat and cool buildings. This results in smaller energy bills for the people living or working in those buildings and causes less pollution from power plants. Steel Sandwich Panel Is An Eco-Friendly Choice For Builders This material is also sustainable and recyclable, which makes it a superior option for eco-friendly construction. Now, with sandwich panel steel, builders are not just benefitting their projects but the planet as well.