Semiconductors are crucial for countless devices that we use on a daily basis, including smartphones and computer. These tiny pieces are what help our devices function. A semiconductor clean room is where these critical technologies are developed and manufactured. Huajing understand the importance of semiconductor clean room in the production of high quality semiconductors.

Semiconductor clean rooms are an essential component of producing high-quality semiconductors. What a clean room, you ask? This is a special room that hepa fan filter unit price does not let dirt in and has microscopic pollutants like dust and microbes on very low level. Even the smallest particles can alter the quality of a semiconductor. This why a clean room is so very essential! Because the air in a semiconductor clean room is filtered, or cleaned too removal from harmful particles. If too many tiny particles were in the air, it could damage the semiconductors being manufactured and compromise the entire process.

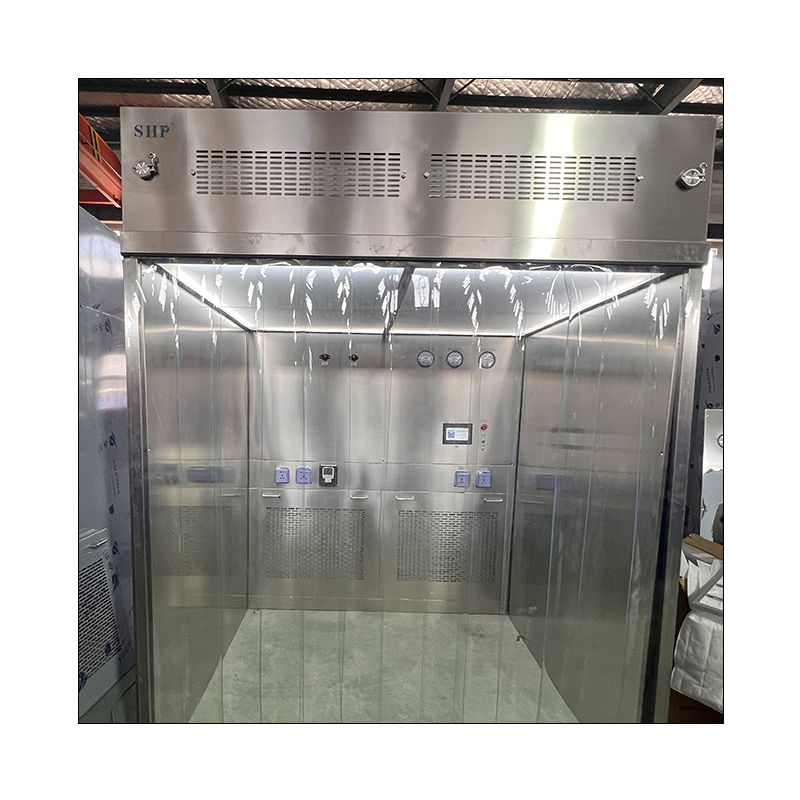

A semiconductor clean room will look and feel quite different when you step into one as compared to a normal room. There are special clothes that workers need to put on before entering the clean room of the semiconductors being manufactured. Immersed in a clean room is this chip-making workbench. This clean room hepa fan filter unit workbench is specifically meant to keep clean, with smooth metal surfaces that resist dust collecting and getting inside the semis.

Semiconductor clean room also plays a significant role in the manufacturing process of semiconductors. Making chips requires multiple stages, including etching, deposition, and patterning. Every step in the process can generate minuscule particles that could cause a problem in the next step. That’s equipment fan filter unit the importance of the clean room. Each stage of the process is able to take place without issue because controlling the environment carefully.

That is as a result of many are fascinated with the making of prime quality semiconductors. Etching is the first step in the process. It removes unwanted material from the semiconductor with great care. It has to be super-precise and therefore takes place in a cleanroom — so there isn't any dirt or dust or anything around. Once etching is completed, we are left with some patterns, called deposition. It ventilator filter unit is here that materials are layered to form the part that make the chip work. Next, a special process called lithography transfers the design of the circuits from a photo mask to the semiconductor. Cleanliness is of

Even a of dust can severely impair a semiconductor's function, so a semiconductor clean room is crucial. These dust, chemicals and other particle are called contaminants and are not good. The environment in the clean room is controlled, with the air filtered to remove particles of dust and other materials, allowing for the chip production process to happen in a fresh and safe setting. If the air has too many pollutants, This ensures that a fan filter unit the semiconductors are manufactured at peak quality, which leads to their improved performance and higher yield.