- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

As a leading supplier of cleanroom system and cleanroom productsSHP Group is an company that prides itself both on technicalexpertise as well as next level customer care.SHP offers Cleanroomsolutions to meet our clients' particular requirements specialized forpharmaceutical, biotechnology and microelectronic cleanrooms.We also provide a range of Clean Room products including wallpanel, door & window and a series of clean room equipment.

As a leading supplier of cleanroom system and cleanroom productsSHP Group is an company that prides itself both on technicalexpertise as well as next level customer care.SHP offers Cleanroomsolutions to meet our clients' particular requirements specialized forpharmaceutical, biotechnology and microelectronic cleanrooms.We also provide a range of Clean Room products including wallpanel, door & window and a series of clean room equipment.

Cleanrooms are essential to any manufacturing process where particulate contamination can affect the quality of goods produced. Specific clean room classifications and ISO class code descriptions provide protective guidelines and secure environments through controlled air filtration, which lowers the possibility of product contamination or large particulate interference within critical process manufacturing. Specific cleanroom requirements and ISO 14644-1 cleanroom standards are used to protect consumers from any potential flaw or mishandling of a product.

Additionally, clean room classifications require that positive pressure is continuously maintained while the cleanroom is operational. This process prevents contaminated air from flowing back within the clean air environment. This process allows clean filtered air to continuously flows from clean to less-clean spaces, allowing for continual air movement.

Core systems of cleanrooms: structure, air conditioning and HVAC systems

The core value of a cleanroom lies in achieving a stable dust-free and sterile environment through "structural sealing + environmental regulation". Its structural system serves as the fundamental carrier, while the air conditioning and HVAC systems are the core of environmental parameter control. The three parties work in coordination to jointly meet the requirements of international standards for key indicators such as cleanliness, temperature and humidity, and pressure difference.

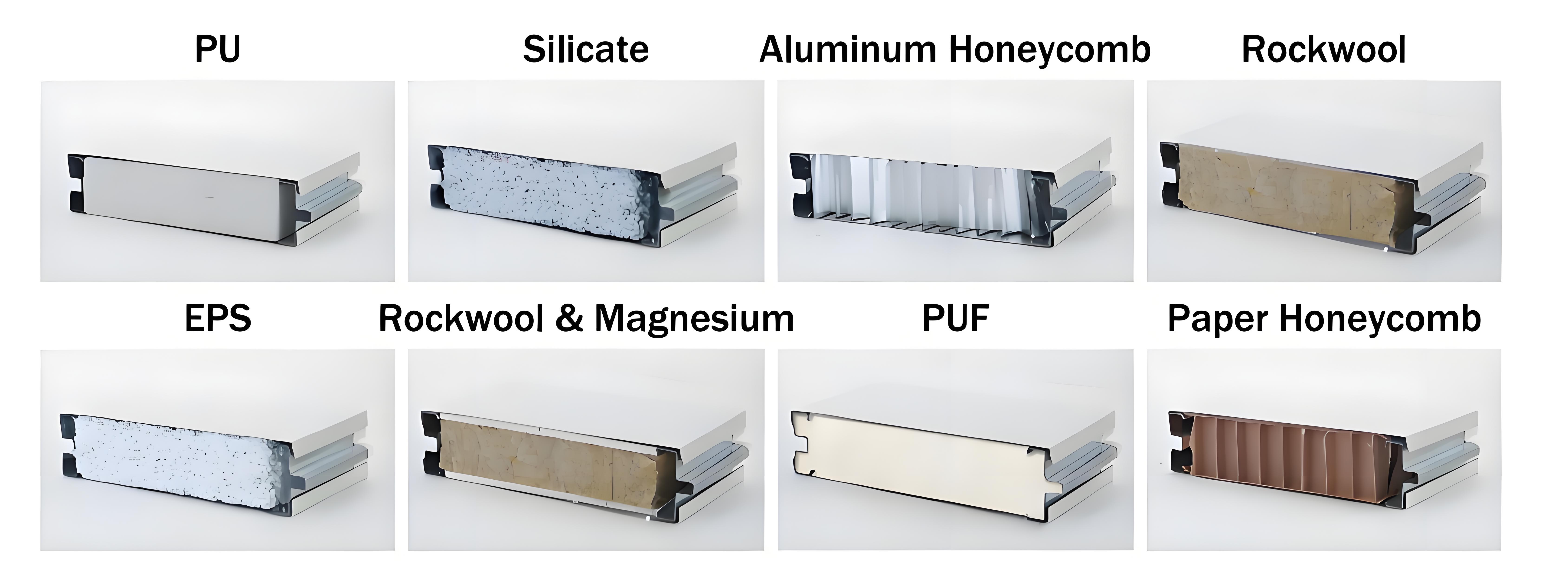

- cleanroom Structure System: The basic carrier for sealing and cleanliness

The core difference between the cleanroom structural system and ordinary buildings lies in "seamless sealing, anti-pollution and easy cleaning". It mainly consists of four parts: the enclosure structure, the floor system, the wall system and the ceiling system, which jointly build a closed clean space.

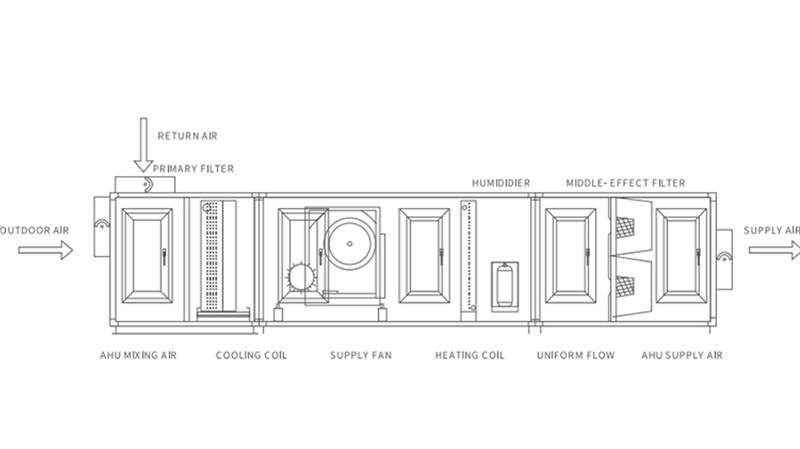

2. air conditioning system: The core for precise control of temperature, humidity and cleanliness

The air conditioning system in a cleanroom is not an ordinary comfort air conditioning system. Its core function is to achieve air purification through high-efficiency filtration on the basis of "temperature and humidity control", and at the same time, in combination with the design of air flow organization, avoid cross-contamination in the clean area. The system adopts an architecture of "centralized processing + zoned distribution" to ensure the stability of parameters in each area.

System composition and workflow

Air Handling Unit (AHU)

Air supply system

Return air system

Exhaust system

Intelligent control

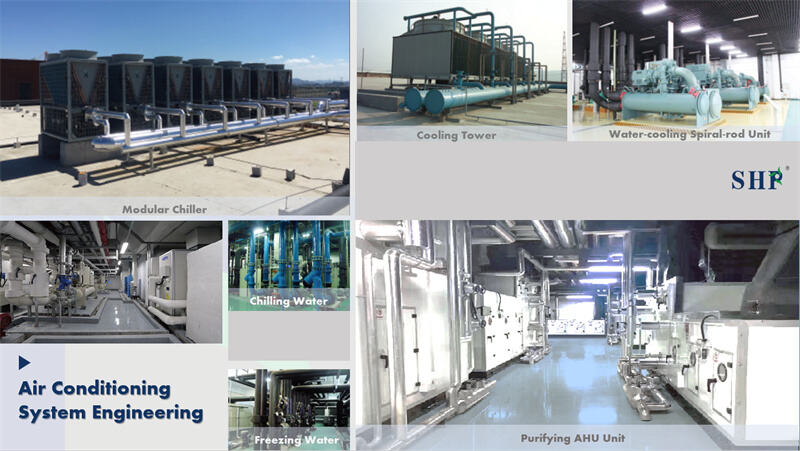

3. cleanroom HVAC System: Stable Assurance of Airflow and Pressure Difference

The HVAC system of a cleanroom is an extension and supplement to the air conditioning system. Its core function is to prevent the clean area from being contaminated by the non-clean area through "air flow organization optimization + pressure difference control", while ensuring the comfort of personnel and the heat dissipation requirements of equipment. Its design is deeply coordinated with the air conditioning system, jointly forming the environmental control network of the clean room.

Core functions and system composition

Differential pressure control system

Ventilation and heat dissipation system

Piping and insulation systems

CLEANROOM EQUIPMENT:

Cleanrooms are essential to any manufacturing process where particulate contamination can affect the quality of goods produced. Specific clean room classifications and ISO class code descriptions provide protective guidelines and secure environments through controlled air filtration, which lowers the possibility of product contamination or large particulate interference within critical process manufacturing. Specific cleanroom requirements and ISO 14644-1 cleanroom standards are used to protect consumers from any potential flaw or mishandling of a product.

Additionally, clean room classifications require that positive pressure is continuously maintained while the cleanroom is operational. This process prevents contaminated air from flowing back within the clean air environment. This process allows clean

filtered air to continuously flows from clean to less-clean spaces, allowing for continual air movement.

ABOUT OUR FACTORY:

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

IT

IT

KO

KO

PL

PL

PT

PT

RU

RU

RO

RO

ES

ES

SV

SV

ID

ID

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

SW

SW

BE

BE

UR

UR

BN

BN

BS

BS

MR

MR

MN

MN

PA

PA

UK

UK

NL

NL

NO

NO

SK

SK

LO

LO

LA

LA