- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

PRODUCTS OVERVIEW

SHP CLEANROOM PRODUCTS OVERVIEW

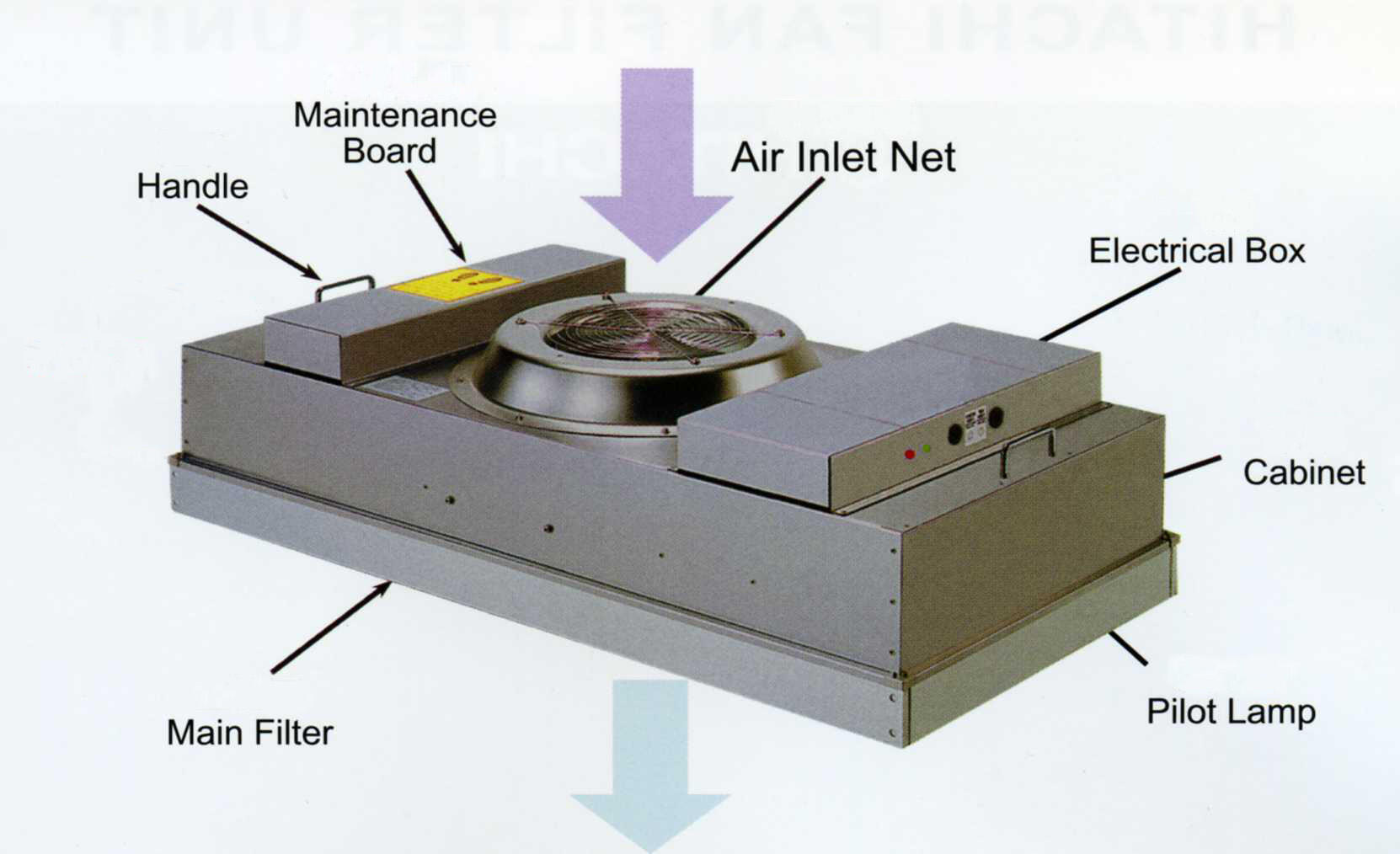

ABOUT FFU:

Product information:

The fan filter unit is a self-powered terminal air supply device with filtering function, the fan sucks in air from the top and filters it through the HEPA filter in order to create clean air and evenly send out from the air outlet, it provides stable and strict air environment control for cleanrooms. The fan filter unit can be connected in modules to meet the needs of different enterprises and scientific research for different clean environments.

| Dimensions(L*W*H) | 1175*575*350mm, 1175*875*350mm, 1175*575*350mm, Customized. |

| Air Velocity | 0.45m/s |

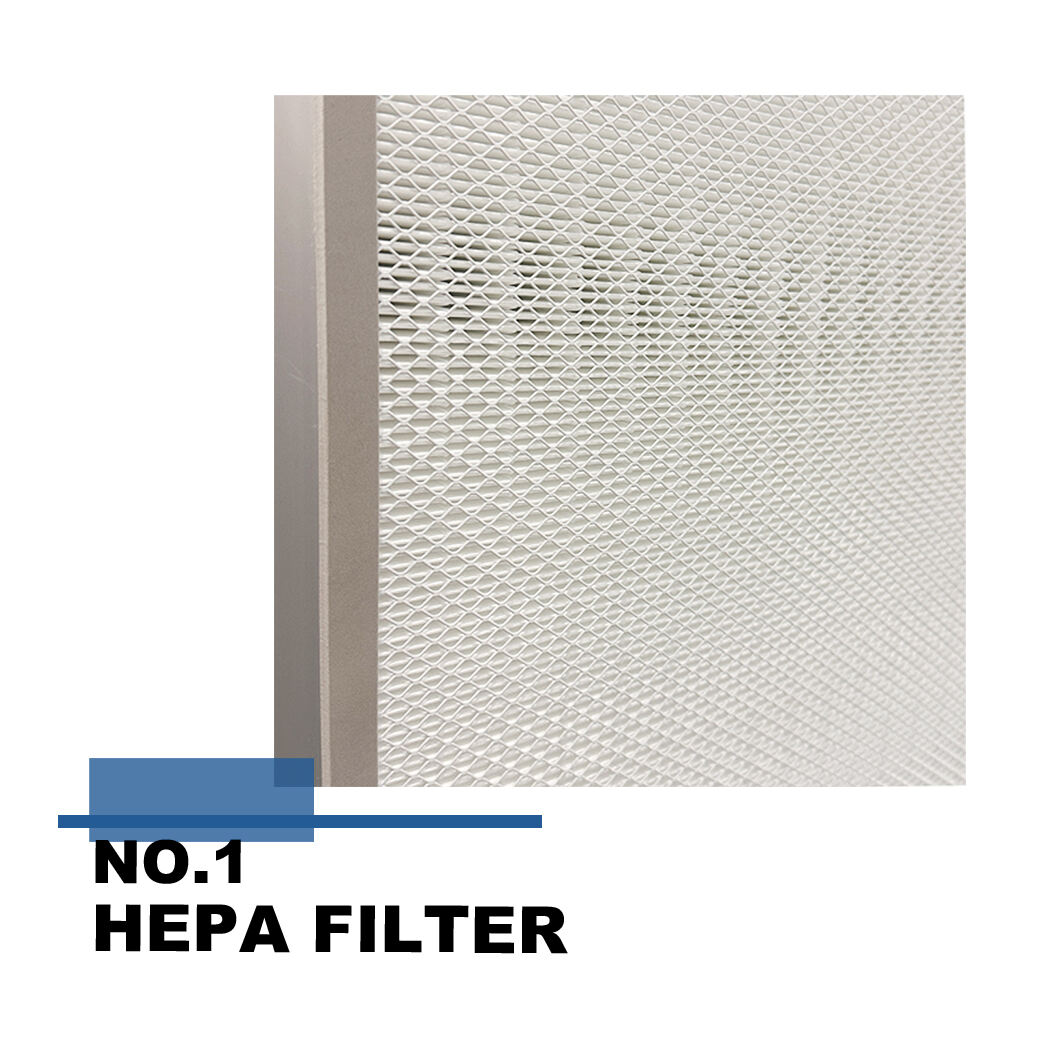

| Filter | HEPA ≥99.995% @0.3micron or ULPA≥99.995%@0.12micron |

| Noise | ≤65db |

| Power | 220V, 50Hz |

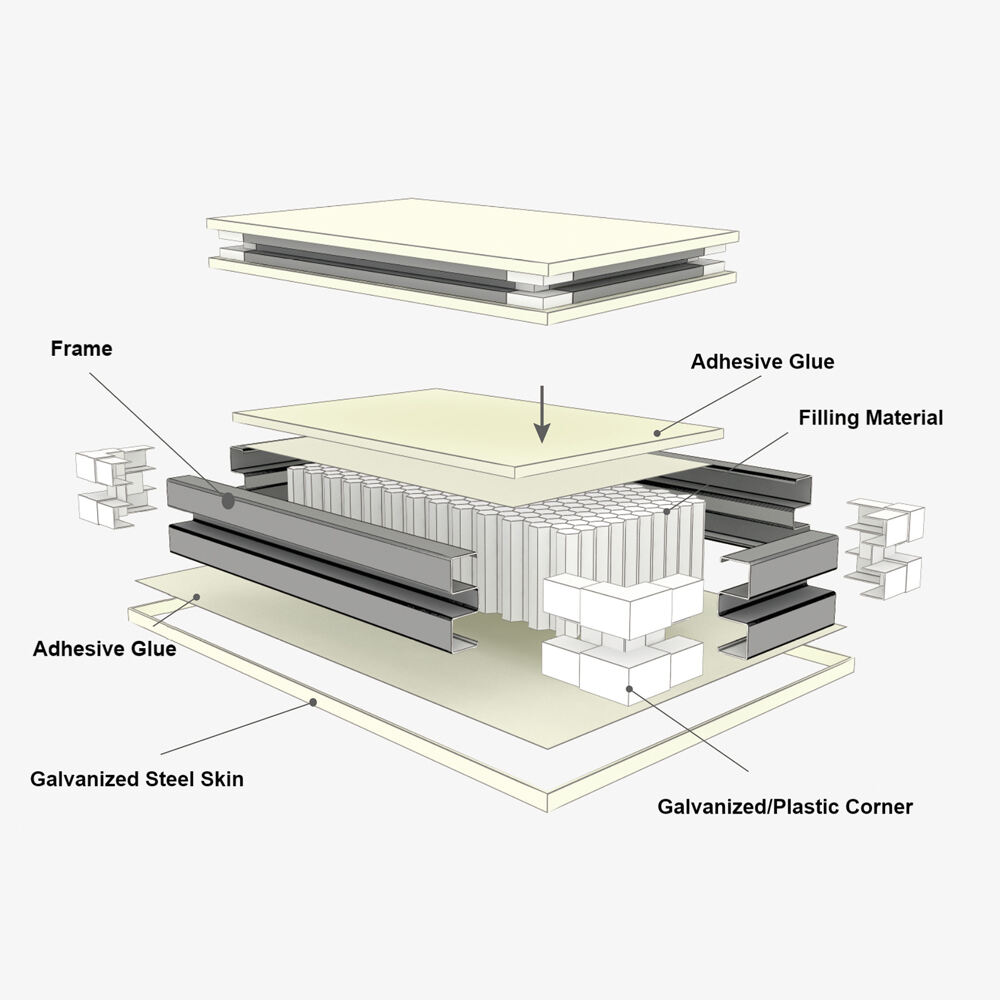

| Material | SS304/Powder Coated Galvanized Steel |

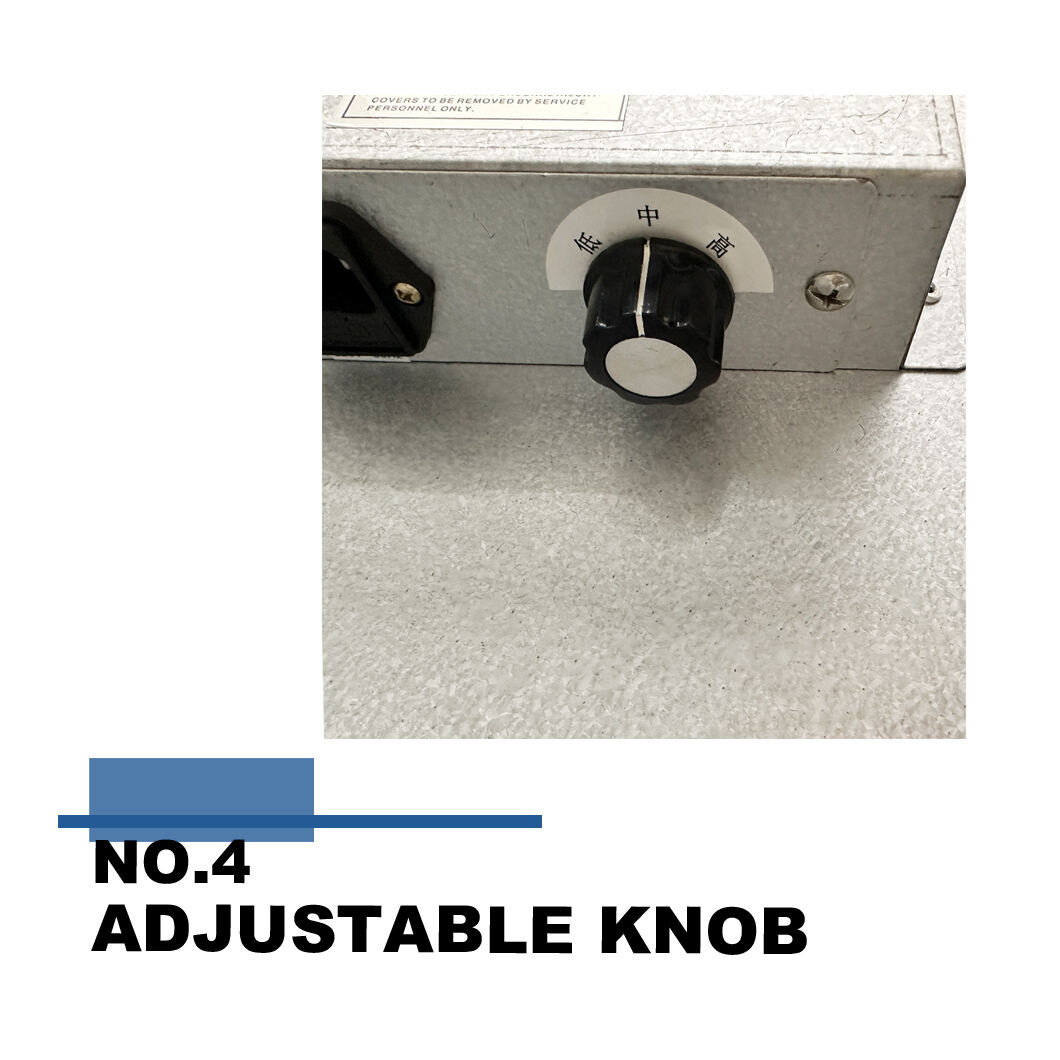

| Controller | Speed adjustor/Speed Indicator |

-

1. Hepa Filter

-

2. Material

-

3. Satety Net

-

4. Adjustable Knob

Intelligent Control System: Upgrade Cleanroom Management

An optional intelligent group control system is available, supporting both individual and regional intelligent control modes. Through the host and PC terminals, real-time monitor the operating status of all FFUs and intuitively view wind speed and energy consumption data. The system dynamically adjusts the parameters of zoned FFUs based on cleanliness sensor data, balancing purification efficiency and energy-saving needs, and is suitable for large-scale cleanrooms.

Wide Applications Across Multiple Industries

Deeply applied in precision industries such as semiconductor manufacturing, liquid crystal display, and electronic component production; suitable for places with strict cleanliness requirements including biopharmaceuticals, food processing, and hospital operating rooms. It can independently create local Class 100 clean areas, be combined into ultra-clean production lines, or assist in manufacturing clean transfer cabinets and storage cabinets, helping to quickly build standard-compliant clean spaces.

Maintenance Tips

Regularly check filter resistance and replace it promptly when there is an abnormal increase. The conventional service life of HEPA/ULPA filters is 1-3 years, adjusted according to the operating environment.Avoid frequent start-stop of the equipment. Keep the surrounding air clean during operation to reduce impurities that accelerate the wear of fans and filters.Clean the device shell regularly and cut off the power supply before maintenance to ensure operational safety.

Customization Services

If you need special dimensions, materials, filtration levels, or control system configurations, please feel free to contact us. We will tailor an exclusive FFU purification solution for you!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

IT

IT

KO

KO

PL

PL

PT

PT

RU

RU

RO

RO

ES

ES

SV

SV

ID

ID

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

SW

SW

BE

BE

UR

UR

BN

BN

BS

BS

MR

MR

MN

MN

PA

PA

UK

UK

NL

NL

NO

NO

SK

SK

LO

LO

LA

LA